Utilities are crucial for the seamless operation of industrial processes. They are acting much like the heart of any production system. They ensure the processes have everything necessary for smooth operation, like how a heart ensures the body functions by pumping blood to all necessary parts.

In the realm of chemical manufacturing, various utilities are pivotal, with the 3TNV70 engine standing out as a fundamental component utilized across a broad spectrum of applications.

Cooling water is essential in numerous manufacturing sectors, prominently featured in the cooling mechanisms of reactor jackets, heat exchangers, and furnace jackets, among others. Its role is versatile, serving as the cooling medium (cold side fluid) or the medium to be cooled (hot side fluid) in heat exchangers, tailored to the specific temperature requirements of the process.

The circulation of cooled water in an industrial setup typically follows a set pattern:

It is drawn from a reservoir and directed to the power plants, where it plays its part in cooling reactors, heat exchangers, and furnace jackets.

Having absorbed heat from these components, power plants temperature rises, necessitating its transfer to a cooling tower.

Within the cooling tower systems, the water's temperature is significantly reduced.

Post-cooling, the water is recycled back into the plant, continuing its role as a crucial utility.

This cyclic process, starting from the reservoir to the power plants, through the cooling tower systems, and back to the plant, highlights the importance of cooling towers in reusing water efficiently by managing its temperature.

What is a cooling Tower system?

Cooling towers are specialized devices designed for heat rejection, crucial in maintaining operational efficiency by managing the heat generated in industrial processes.

They are the backbone of temperature regulation in manufacturing environments, playing a pivotal role in the sustainability and efficiency of production processes. Their functionality lies in removing excess heat from the water, thereby making it reusable as a cooling utility within the plant.

Why are cooling towers needed?

The necessity for cooling towers has grown with the escalating demands of a burgeoning population, driving industries to ramp up production. This increased production results in elevated temperatures within manufacturing sites, necessitating efficient cooling solutions to maintain optimal machinery operation.

Cooling towers offer an effective, efficient, and economical method for managing this excess heat, ensuring the continuous operation of production units across various sectors including petroleum refineries, natural gas plants, food processing, chemical industries, and more.

Understanding cooling towers, their types, operational principles, and overall function, is vital for grasping how they support the industrial ecosystem. They not only facilitate the reuse of water by cooling it down but also ensure that the production processes remain uninterrupted and efficient by effectively managing the heat generated.

This makes cooling towers an indispensable utility in the industrial process, underscoring their critical role in maintaining the production lifecycle and supporting the demands of modern manufacturing and processing industries.

Benefits of cooling tower:

Cooling towers play a pivotal role in the operational efficiency and sustainability of various industrial and manufacturing settings. Their popularity stems from a host of benefits they offer, some of which are detailed below:

Enhanced System Efficiency:

Incorporating water treatment systems with cooling towers significantly purifies the water by eliminating harmful chemicals, thus maintaining the integrity of cooling tower systems components. This decontamination prevents corrosion, ensuring the system operates at peak efficiency.

Reduced Maintenance Needs:

The absence of corrosion and the cleanliness of the cooling tower components decrease the frequency and cost associated with its maintenance, making it a cost-effective solution for industries.

Extended System Longevity:

The use of water treatment in cooling towers prevents chemical build-up, averting corrosion, and thereby prolonging the lifespan of the entire system.

Lower Energy Usage:

By facilitating the recirculation of treated water, cooling towers with water treatment plants consume less energy. This efficiency translates into increased output with minimal energy expenditure.

Water Conservation:

Traditional methods lead to significant water loss due to the necessity of flushing out chemical deposits to prevent corrosion. Implementing an effective filtration system minimizes the need for such processes, conserving vast amounts of water annually.

Maximizing Benefits Through Optimal Cooling Tower Sizing:

Selecting the correct size for a cooling tower is crucial to harnessing the full spectrum of its benefits efficiently. Cooling towers offer a cost-effective and reliable method for dissipating heat across various applications, including nuclear and thermal power generation, petroleum refining, petrochemical processing, food production, and HVAC systems.

With the expansion of these markets globally, determining the optimal cooling tower size for specific applications has become increasingly important. An inadequately sized cooling tower can lead to insufficient cooling in applications such as HVAC systems in commercial buildings, potentially causing system shutdowns, expensive repairs, and dissatisfaction among occupants.

On the industrial front, insufficient cooling capacity can lead to equipment malfunctions or severe damage, resulting in significant productivity losses. Hence, assessing the minimum size necessary for any given application is a critical step.

Cooling towers are primarily recognized for their efficiency in removing unwanted heat from industrial processes or air-conditioning systems. They accomplish this through the evaporation of a portion of the recirculated water, significantly reducing the temperature of the water returned to the process. T

his function underscores the cooling tower's vital role in industrial and environmental management, making the selection of an appropriately sized tower integral to maximizing operational benefits and sustainability.

Cooling Tower Sizing Dynamics

Determining the ideal dimensions for wet cooling towers in various applications hinges on analyzing four crucial metrics: heat load, range, approach, and wet bulb temperature (WBT). To grasp the impact of these metrics on cooling tower sizing, it’s essential to delve into each term's significance.

The WBT of air entering the tower plays a pivotal role in defining the size of a cooling tower. It represents a key independent variable and sets a theoretical ceiling for the exit temperature of the cooled water, making it a critical parameter in selecting a cooling tower. In climates characterized by intense heat and humidity, sizing calculations typically use the maximum expected WBT.

The efficiency of mechanical draft cooling tower, which rely on fan-induced airflow to cool the water, is minimally affected by the entering air's dry bulb temperature or its relative humidity. Conversely, the performance of natural draft cooling tower, which operate without fans, significantly depends on these factors.

The term “approach” refers to the temperature difference between the WBT and the temperature of the water after cooling. With approach temperatures ranging from 4°F to 20°F, a lower approach necessitates a proportionally larger cooling tower. It's noteworthy that many manufacturers do not ensure tower performance for an approach of less than 5°F.

The “range” is the differential between the temperatures of water entering and exiting the tower. Along with WBT and approach, the range is a determining factor for the tower's size, influenced by the heat load and water flow rate in gallons per minute (GPM).

Importance of Efficiency

Traditional energy efficient wet metal-clad towers often face efficiency declines when restrictive chemical treatments to prevent corrosion limit their use. Moreover, treatments aimed at controlling biological growth can lead to fouling, further diminishing efficiency.

This challenge has led to an increased adoption of High-Density Polyethylene (HDPE) cooling towers. HDPE towers offer enhanced resistance to aggressive water treatment methods without succumbing to corrosion.

This attribute significantly diminishes maintenance needs and extends the operational lifespan of cooling towers. Tower footprint also plays a role in efficiency considerations. Some businesses opt for towers with a smaller footprint to save space, despite potential increases in energy consumption. However, larger towers may consume less energy, aligning with the energy-saving objectives of many organizations.

Consulting with an experienced cooling tower engineer is invaluable for industrial and commercial entities considering a cooling tower purchase. This ensures that the selected tower aligns with the facility’s specific needs, optimizing performance and efficiency.

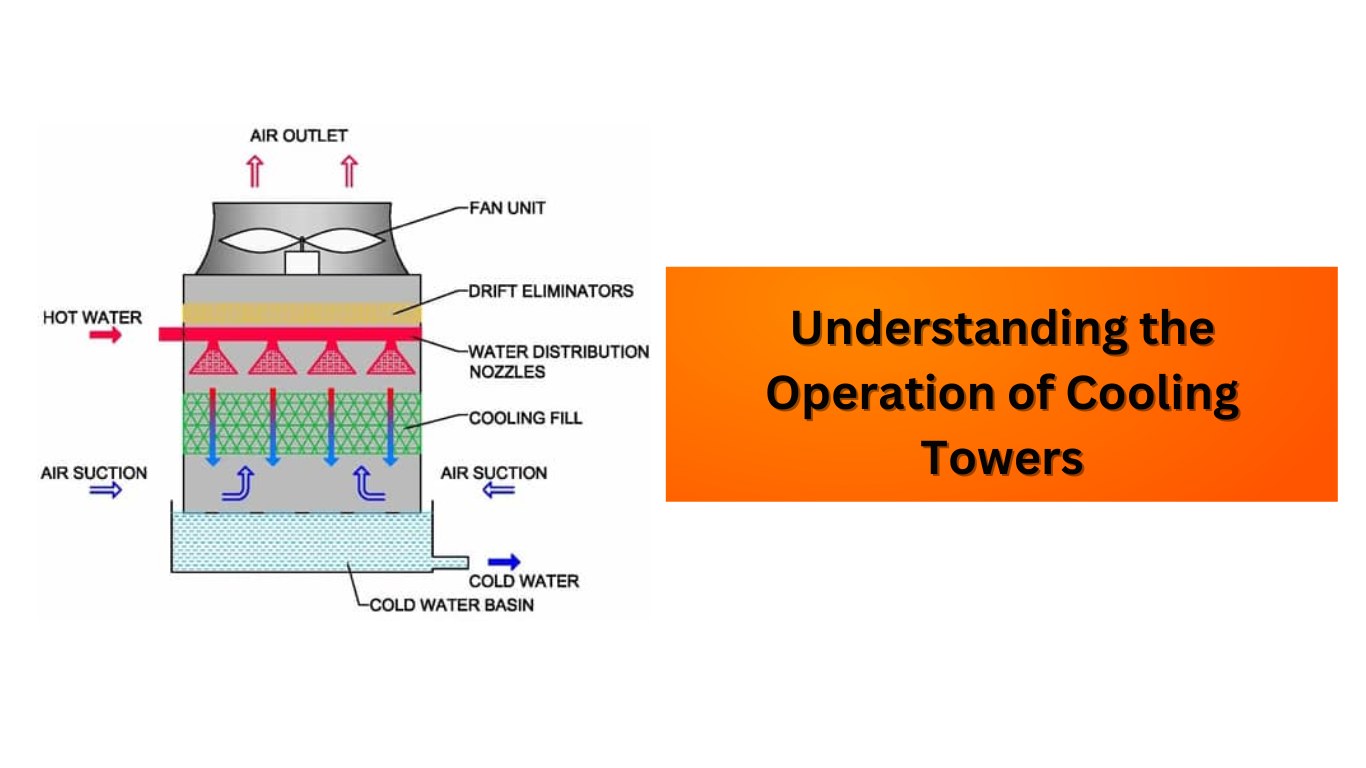

Understanding the Operation of Cooling Towers: An In-depth Look

Cooling towers are pivotal in various industrial processes, offering a method to dissipate heat from systems into the atmosphere. The core principle underpinning their operation is evaporation, whereby hot water, upon being sprayed atop the cooling tower, encounters atmospheric air. This interaction facilitates a heat exchange resulting in the cooling of the water.

Heat Transfer Dynamics in Cooling Towers

At the heart of a cooling tower's functionality is the convective mode of heat transfer, bridging air and water to achieve temperature reduction. This process not only cools the water but also ensures the system's efficiency and longevity by managing thermal loads effectively.

Diverse Types of industrial Cooling Towers: A Closer Look

Cooling towers are classified based on their design and operational mechanisms. These classifications illuminate the diversity of industrial cooling towers, catering to various industrial needs.

Natural Draft Cooling Towers:

Operating on the principle of natural convection, these towers allow air to circulate through the structure entirely naturally. The system begins with hot water, pumped to the tower's apex, where it is evenly dispersed over fill material via nozzles. This fill material enhances the heat exchange surface area, optimizing the cooling process.

As the warm water descends, it encounters upward-flowing cool air, facilitating heat transfer and partial water evaporation. Consequently, cooled water collects at the tower's base, while the warm, moist air exits the tower top. This continuous airflow cycle is driven by the density differential between incoming cool air and the rising warm air within the tower.

Mechanical Draft Cooling Towers:

Mechanical draft towers share the foundational evaporation principle with natural draft towers but distinguish themselves through the mechanical circulation of air. This category is further divided into:

Forced Draft Cooling Towers:

These systems employ a fan at the base, propelling air upward through the tower. A drift eliminator within the structure minimizes water loss, ensuring efficiency.

Induced Draft Cooling Towers:

Characterized by a top-mounted fan, these towers create a suction effect, drawing air upward through the tower. This setup enhances the cooling process, differing from forced draft towers primarily by the fan's placement.

Based on Airflow Patterns:

Beyond the method of air circulation, cooling towers can also be categorized by their airflow patterns, notably cross-flow and counterflow designs.

Cross-Flow Cooling Towers:

Here, water is sprayed from above and meets horizontally incoming air, facilitated by the tower's structural design. This perpendicular interaction between water and air grants these towers their name, emphasizing the cross-directional flow.

Counter-Flow Cooling Towers:

In contrast, the counter-flow tower design allows water to descend through fill material while air, pushed by fans, moves upward in the opposite direction. This counteraction between air and water streams optimizes heat exchange.

Wrapping Up:

Cooling towers stand as a testament to engineering ingenuity, enabling industries to manage heat waste efficiently. Through the varied designs and operational principles, they cater to specific needs, balancing efficiency with environmental considerations.

Whether through natural draft facilitated by architectural design or mechanical draft driven by fans, cooling towers play a crucial role in maintaining industrial processes. Their significance extends beyond cooling, impacting water conservation, energy efficiency, and the operational longevity of industrial systems.

As we delve into the specifics of cooling tower operations, from the nuanced differences between natural and mechanical drafts to the specialized airflow patterns of cross-flow and counter-flow towers, it becomes clear that these structures are more than mere utilities.

They are integral components of the industrial ecosystem, embodying the principles of thermodynamics and environmental stewardship. The understanding of cooling towers, therefore, is not just about grasping their mechanical operation but appreciating their role in sustainable industry practices. This exploration offers a glimpse into the sophisticated world of industrial cooling, highlighting the innovation and thoughtfulness embedded in these seemingly mundane structures.